Key Technical Parameters of MHX

Product

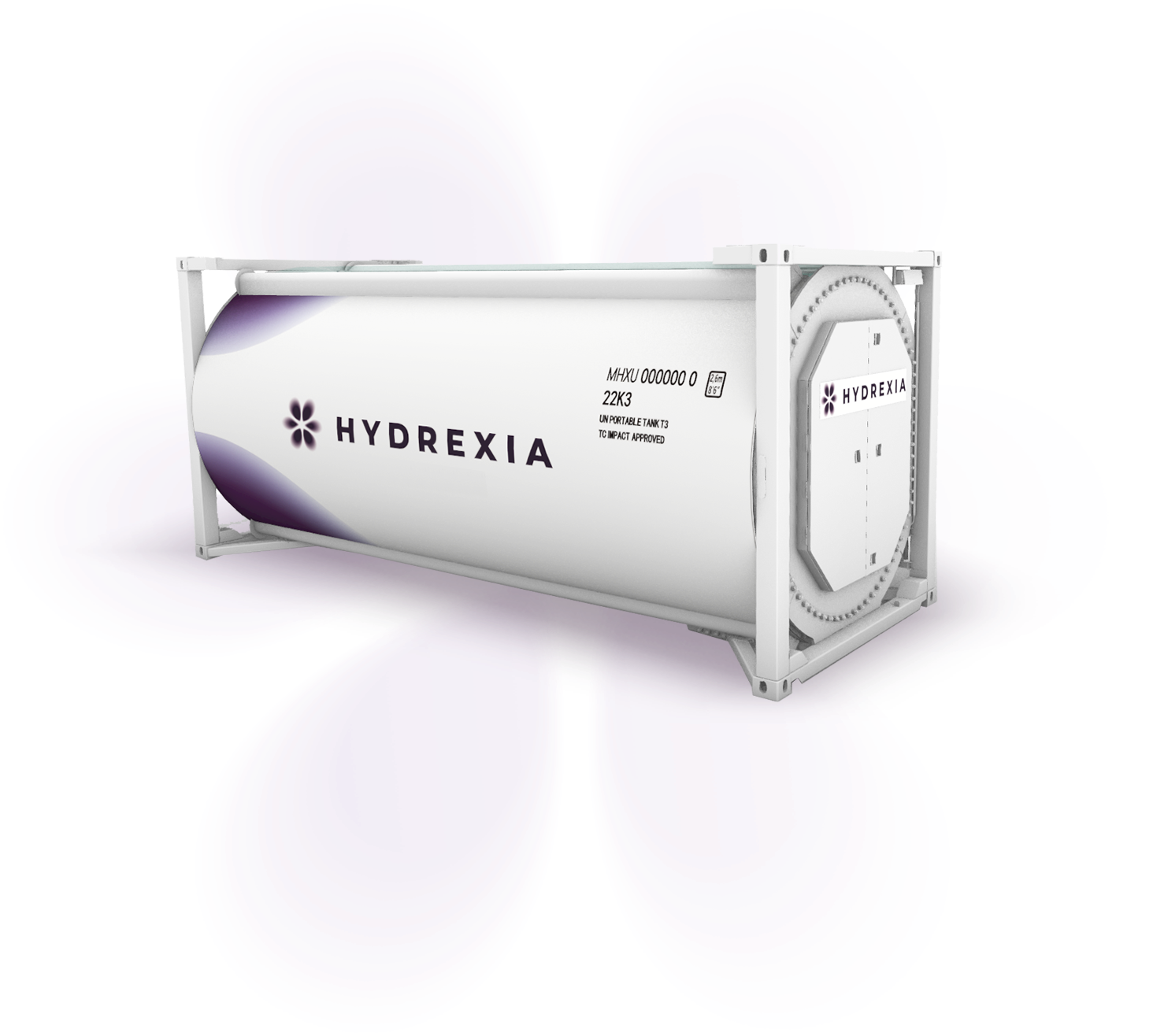

Ton-level magnesium-based solid-state hydrogen storage container(MHX)

Rated hydrogen storage capacity

1.0t

Gravimetric density

6.4wt%

Volumetric density

57.8kg/m

Magnesium alloy loaded per container

15.6t

Max. working pressure

1.2 MPa

Max. hydrogen charging rate

108 kg/h

Max. hydrogen discharging rate

96 kg/h

Economic transport radius

100~500km

Transport mode

Truck, ship & train

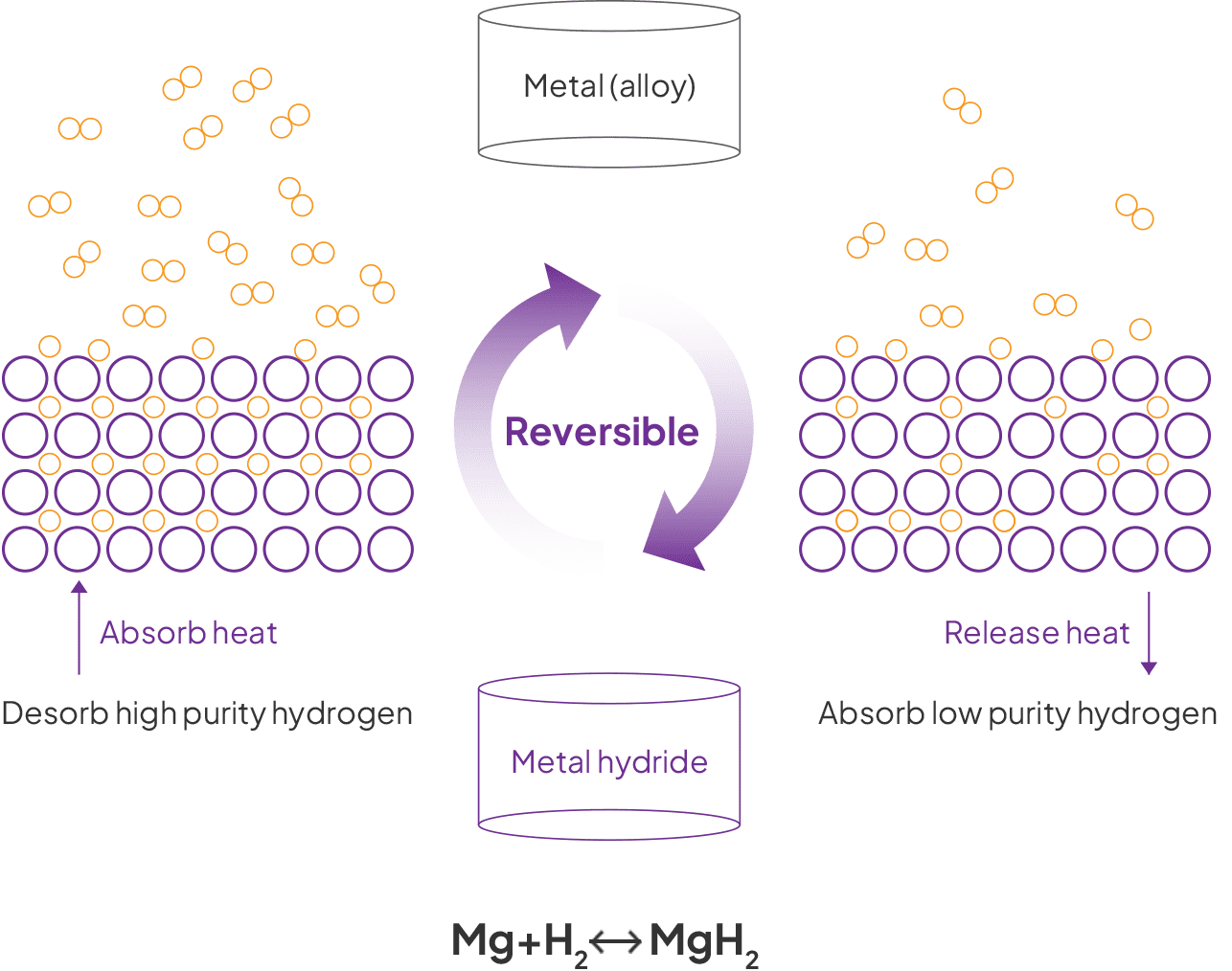

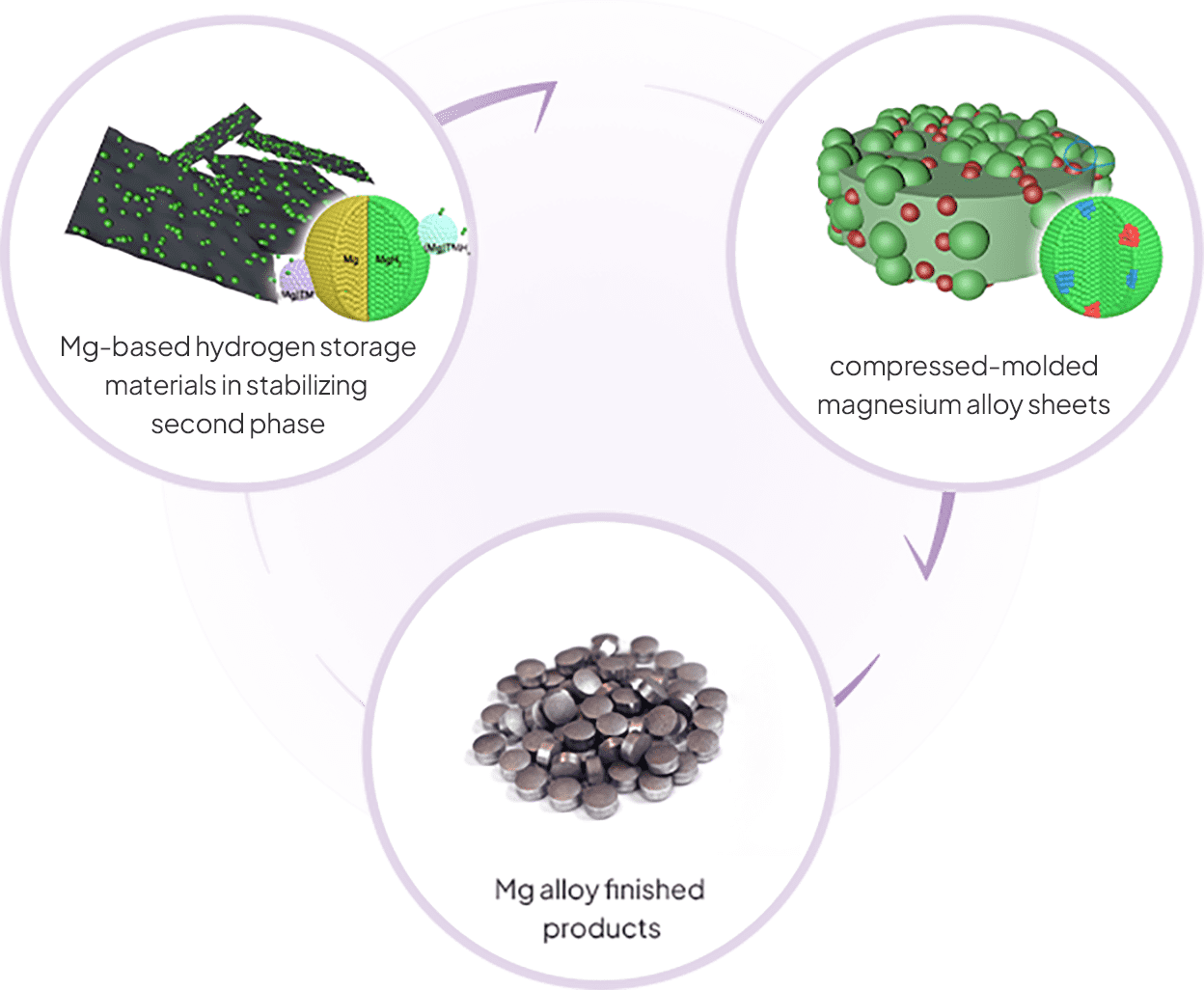

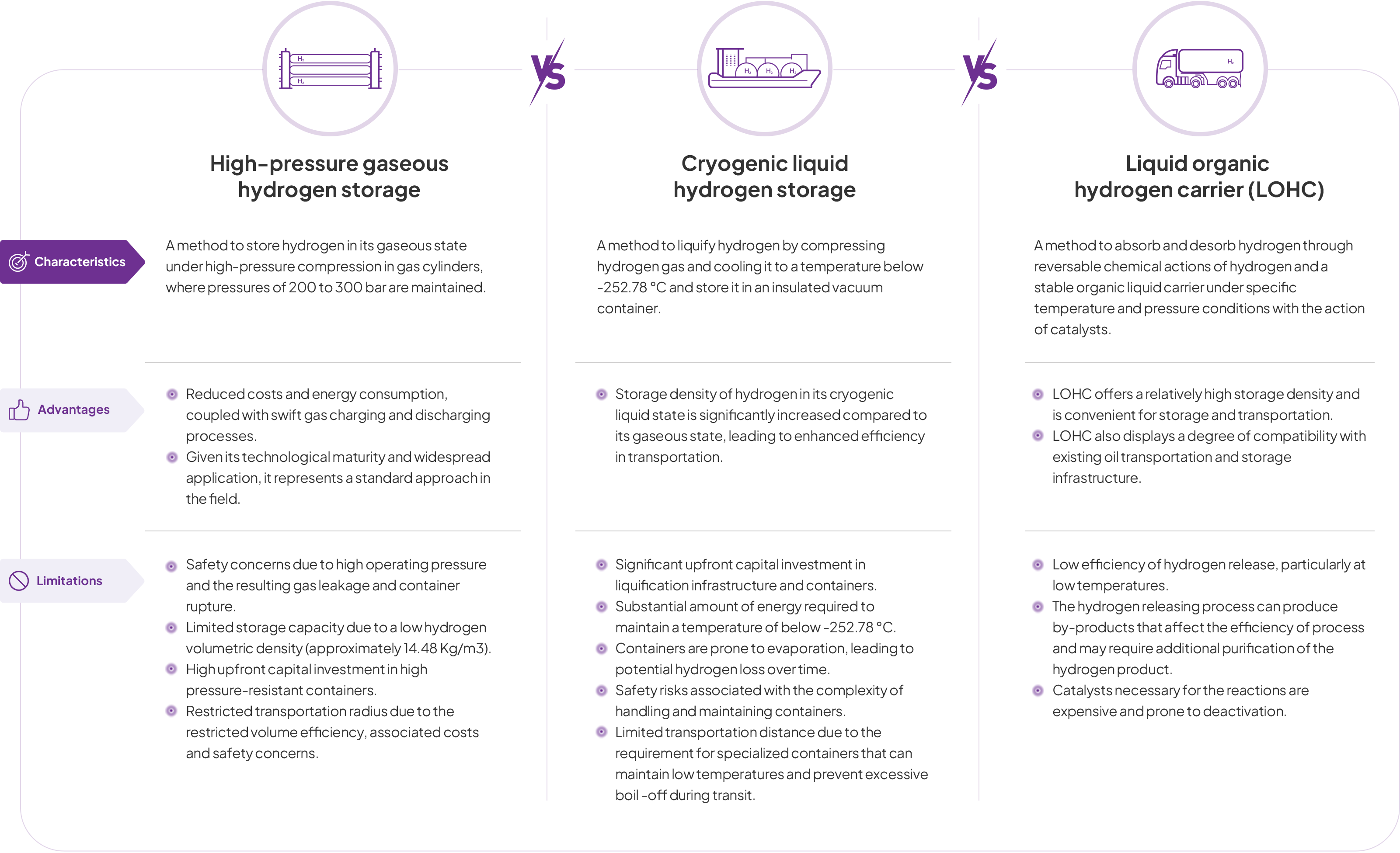

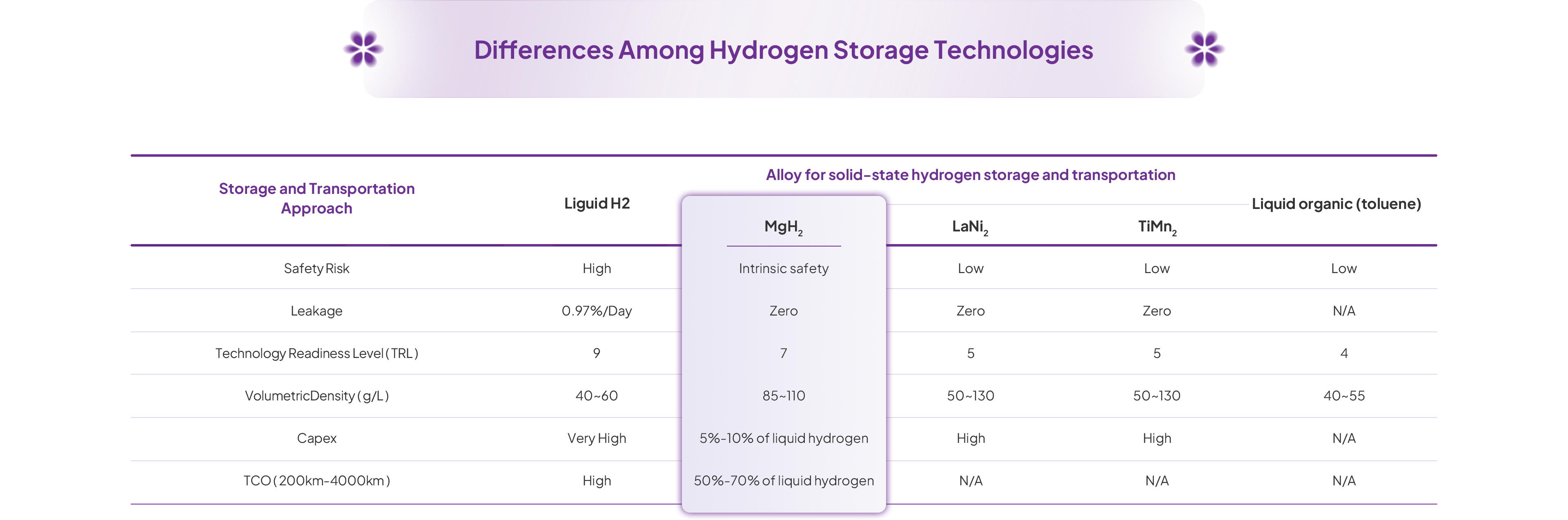

Compared to conventional tube containers used for transporting compressed gaseous or liquid hydrogen, our

MHXes offer the following significant advantages:

Enhanced safety

While conventional tube containers pose considerable safety risks due to potential hydrogen leakage and potential explosions during transit, our magnesium-based hydride stands as a non-flammable and non-explosive solid material, rendering our MHXes exceptionally safe for long-distance transport and use in urban or densely populated areas.

Larger storage capacity

Our standard 20-foot MHXes can carry up to 1 ton of hydrogen in a single trip, which is three to five times the capacity of conventional tube containers, leading to reduced logistics costs and greenhouse gas emissions.

Higher hydrogen purity

The hydrogen released from our MHXes reaches an ultra-purity of 99.999%, immediately usable in fuel cells and various other applications.

Easy transport

Our MHXes are versatile and adaptable for transport via truck, rail, or ship. Their modular design also allows for easy scaling to meet the needs of diverse applications.

Reduced delivery cost

Our MHXes ensure higher cost-effectiveness compared to conventional tube containers, significantly reducing the total cost of hydrogen delivery .

Prolonged lifespan

Our MHXes can function for 4,000 cycles, or approximately 20~25 years, without performance reduction under lab conditions.

Simplified infrastructure requirement

Unlike conventional tube containers that necessitate the use of expensive and maintenance-intensive compressors at hydrogen refueling stations, our MHXes operate at near ambient pressure and temperature with a maximum charging rate of 108kg/h and a maximum discharging rate of 96kg/h. This eliminates the need for costly compressors and their associated maintenance expenses, streamlining the refilling station infrastructure and resulting in more cost-efficient operations.

Higher residual value

Given that the magnesium alloy is highly recyclable, our MHXes retain a substantial residual value at the end of their service life, further reducing costs for our customers.

Compliance

Compliance with American Society of Mechanical Engineers (ASME) BPVC Sec. VIII Div. 1, IMDG, CSC, CCC.

Industrial Applications of Our Solutions

Conventional hydrogen transport methods, whether gaseous or liquid, are usually limited to local or regional distribution. When traveling over a distance of over 100 kilometers, there is a notable uptick in both costs and safety concerns. These challenges have limited the applications of hydrogen in broader industrial contexts. Building on our innovative technology, our solutions provide a safe and cost-effective option for long-distance, high-capacity hydrogen transport, filling a long-standing gap in the market. By significantly extending the geographic area of hydrogen delivery, we are poised to connect hydrogen supply with demands across disparate regions, facilitating a more widespread industrial adoption of hydrogen.

On the hydrogen storage side, our magnesium-based solid-state solutions help enhance the sustainability and resilience in energy infrastructure and have vast potential in various industrial scenarios, including but not limited to photovoltaic energy storage, ocean energy storage, power generation, green ammonia production, green steel manufacturing, and hydrogen refueling stations, significantly contributing to process of decarbonization.