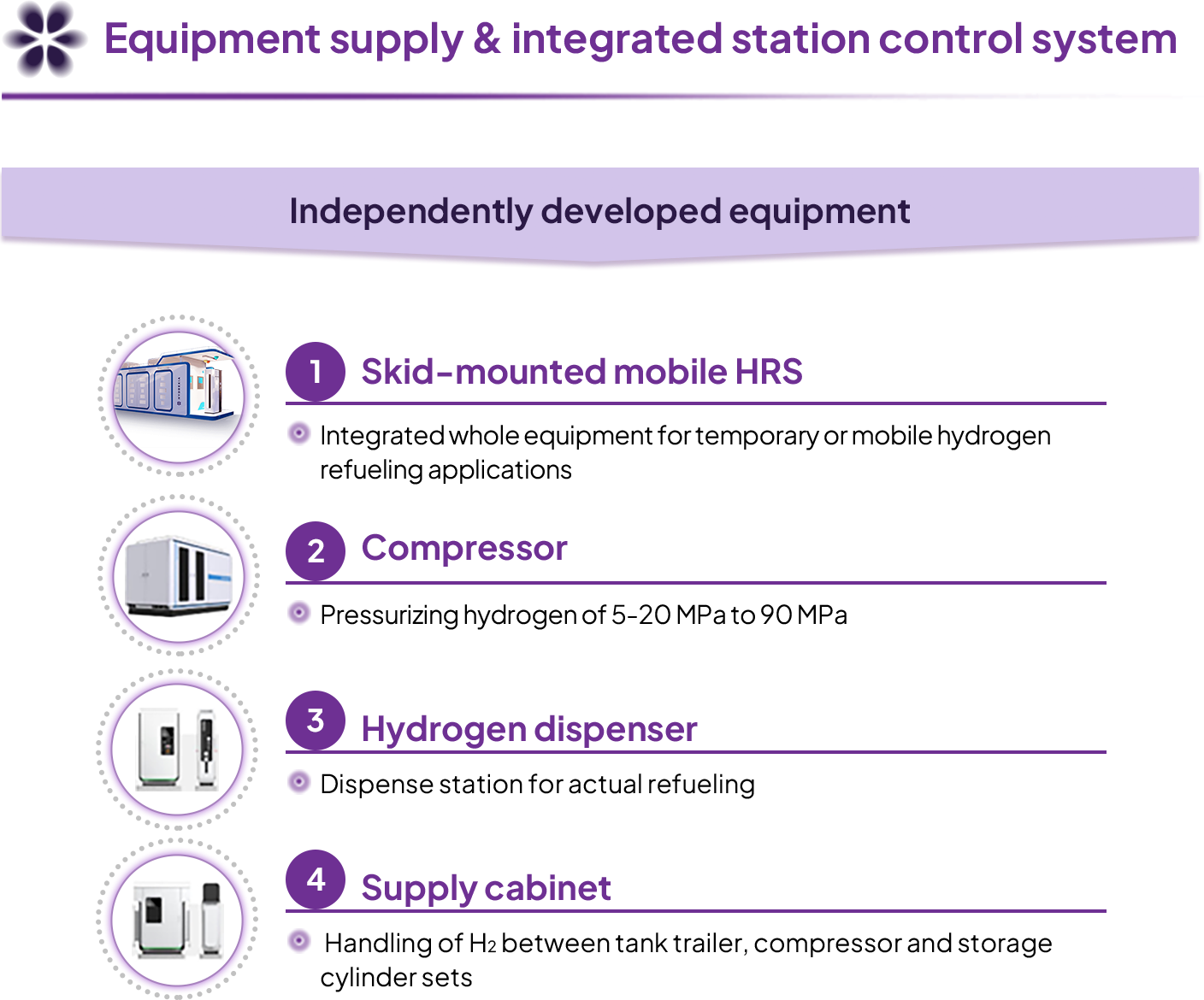

Our solutions primarily encompass the supply and installation of a whole set of HRS equipment, complemented by a customized design of construction plan that aligns with the specific requirements of each site.

We tailor the deployment of our proprietary equipment to fit the scale and specific needs of each HRS. For instance, we perform in-depth calculations that factor in the refueling frequency, timing, and vehicle types, and select the most suitable equipment and parameters to yield maximum performance while minimizing energy consumption. The key equipment deployed at these stations include our specialized hydrogen compressor, dispenser, supply cabinet, cascade control cabinet, nitrogen cabinet, and filling cabinet. We independently design and assemble all the equipment to ensure its quality and reliability.

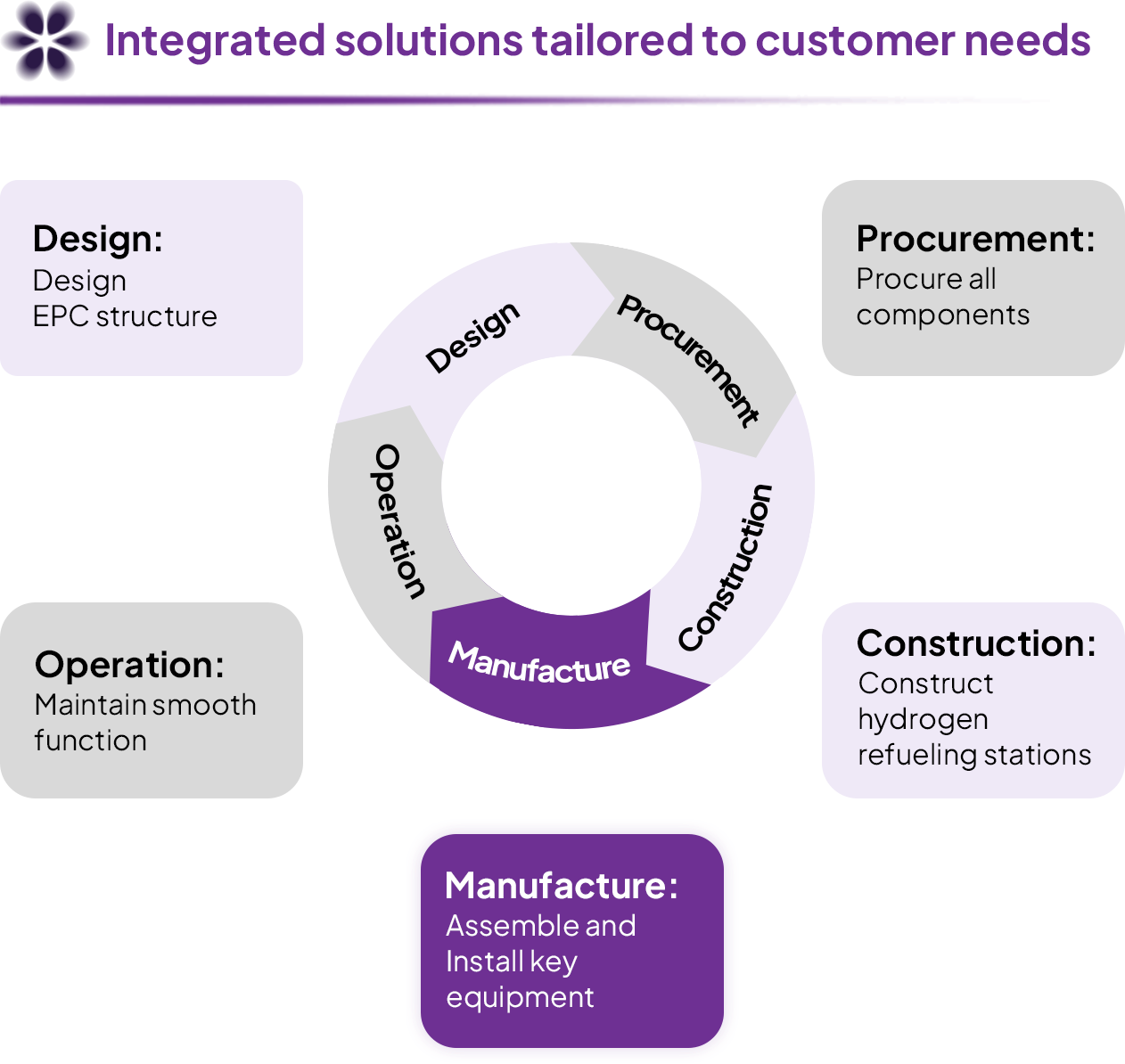

For a certain number of HRSs, we extend our services beyond mere site construction to include ongoing operation and maintenance support. Through over 8 years of development, we have accumulated extensive experience and established a proficient team specializing in the operation and maintenance of HRSs. We have also formulated a set of standardized guidelines and protocols, particularly in terms of equipment operating manuals, record management, emergency plans, and equipment maintenance practices, to ensure the stability, safety, and efficient operation of the stations. We stand out in HRS for our unique and integrated ability in providing customized solutions for the design, installation, and operation of HRSs.