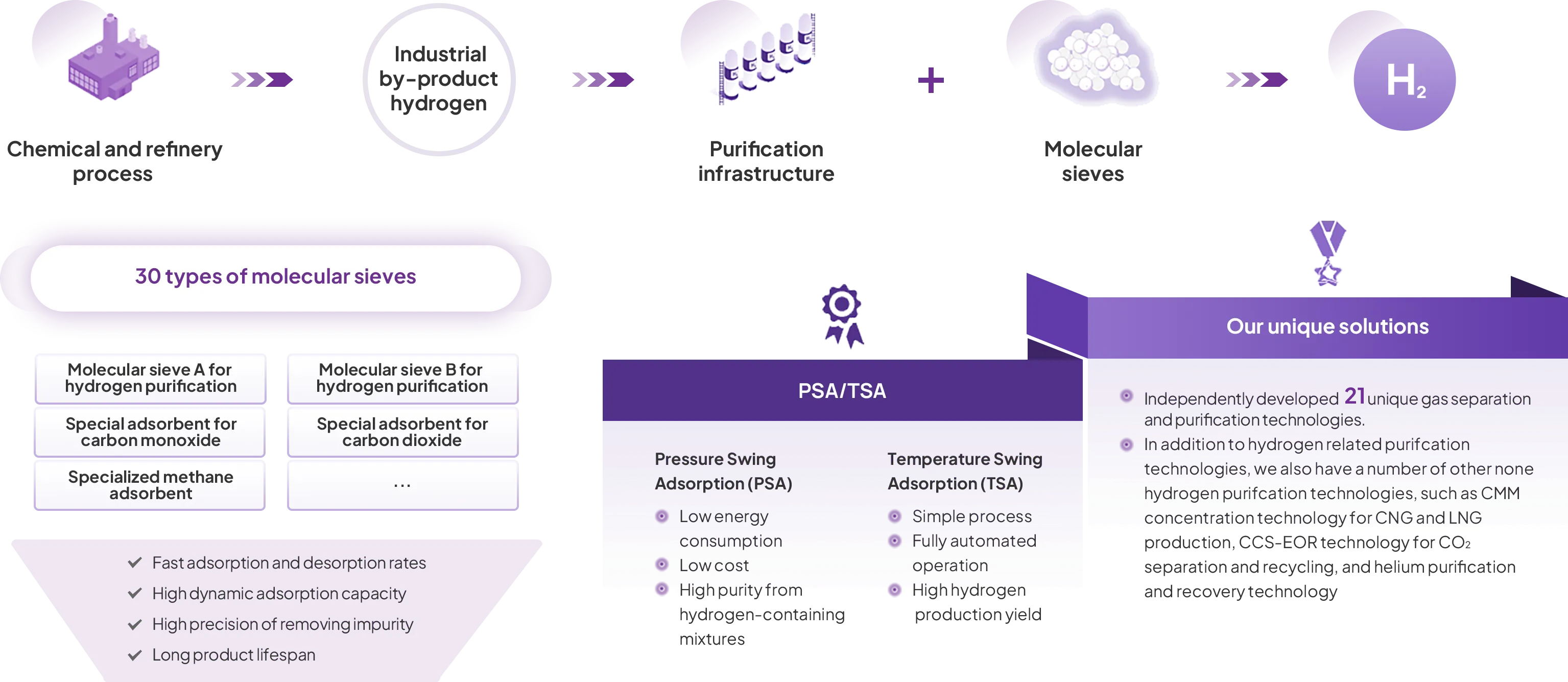

We expanded our solutions and product line to hydrogen production through the acquisition of Sichuan DKT Energy Technology Co. , Ltd. in 2021. Our focus in the field of hydrogen production is primarily on hydrogen separation and purification. Underpinned by our R&D capabilities and decade-long project experiences, we have independently developed 21 gas separation and purification technologies based on the principles of adsorption(PSA/TSA), absorption, membrane separation and catalysis, along with 30 types of proprietary molecular sieves, control valves and comprehensive sets of equipment tailored for diverse applications.

Our technologies are mainly used for extracting and purifying hydrogen from hydrogen-rich waste gases produced in chemical or petrochemical processes, or industrial byproduct hydrogen. By integrating our proprietary molecular sieves and equipment with custom-designed purification processes, our solutions provide efficient, cost-effective, and high-performance hydrogen separation and purification.

The 21 advanced gas separation and purification technologies we have developed are used to meet the needs of various industrial gases. Generally, our unique technologies are characterized using proprietary molecular sieves, as well as our proficiency in customizing suitable processes, and implementing advanced control systems. These technologies in our separation and purification systems help yield high reliability, security, and efficiency within a compact footprint. Compared to conventional methodologies, our technologies achieve increased gas recovery rates and purity level, while reducing energy consumption and operational costs.

Our proprietary suite of technologies comprises of hydrogen separation and purification technologies, mainly including PSA-based hydrogen purification technology, TSA-based hydrogen purification technology, membrane-based hydrogen separation technology, as well as various other gas separation and purification technologies, such as CMM concentration technology for CNG and LNG production, CCS-EOR technology for CO₂ separation and recycling, and helium purification and recovery technology.

PSA-based Hydrogen Purification Technology

TSA-based Hydrogen Purification Technology

Membrane-based Hydrogen Separation Technology

CMM Concentration Technology for CNG and LNG Production

CCS-EOR Technology for CO₂ Separation and Recycling

Helium Purification and Recovery Technology

PSA-based Hydrogen Purification Technology

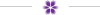

The PSA technology is widely used to separate and purify hydrogen gas from industrial byproduct hydrogen or from hydrogen-rich streams produced via traditional methods. Our unique purification process, combined with our proprietary molecular sieves and equipment, ensures stable and safe operation of hydrogen purification plants and yields high hydrogen recovery rates, while maintaining low operational costs and energy consumption. The chart below illustrates our standard hydrogen separation and purification process.

TSA-based Hydrogen Purification Technology

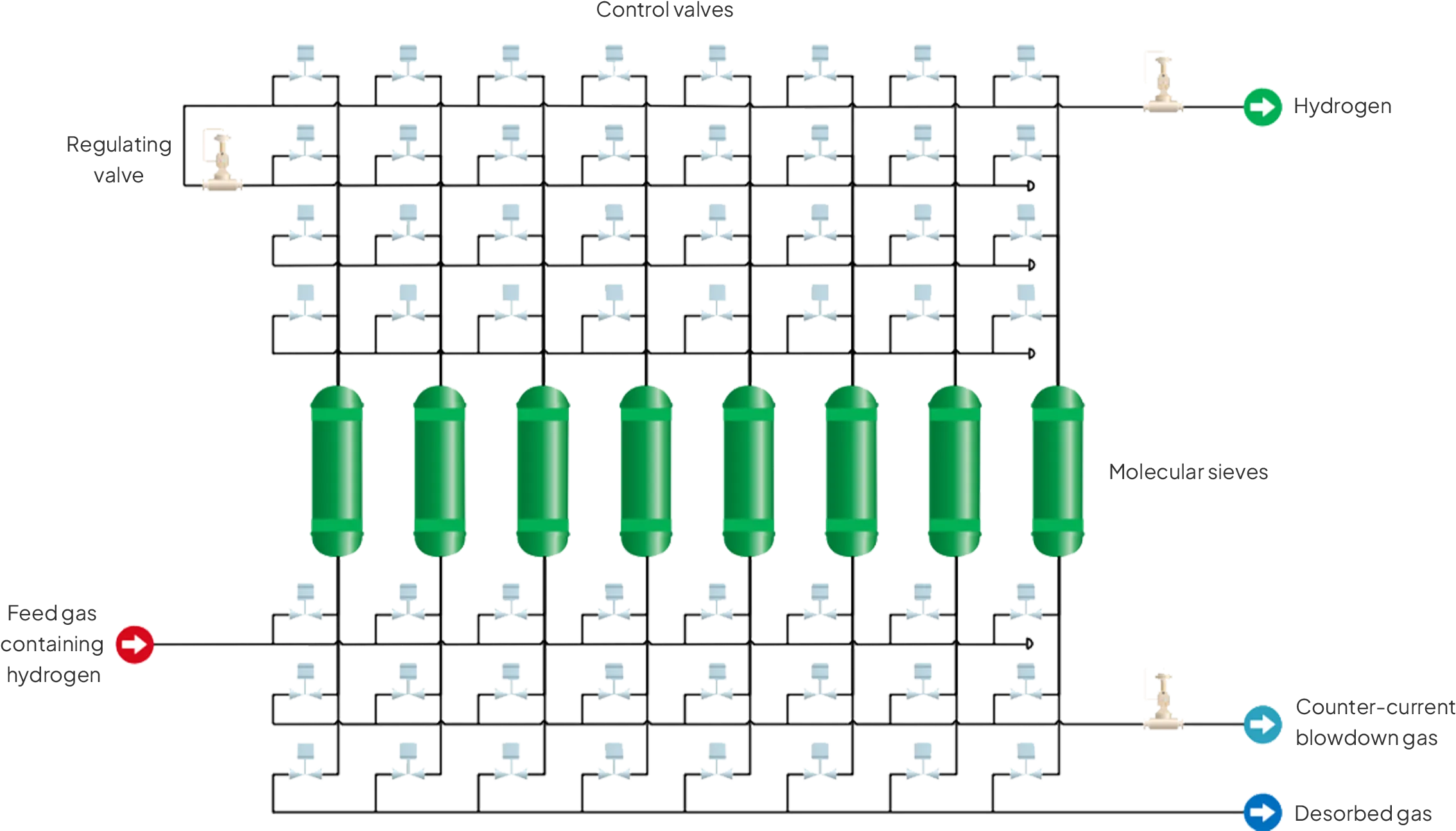

The TSA technology, on the other hand, finds its application in eliminating trace impurities from hydrogen gas such as hydrogen produced through water electrolysis. While TSA and PSA technologies share similarities in their operational processes, TSA primarily relies on temperature fluctuations to separate gas or liquid mixtures. The adsorption capacity of molecular sieves for specific impurity molecules typically varies with temperature shifts. By adjusting the temperature during the process, we can regulate the adsorption and desorption of target impurities, thereby facilitating the purification of hydrogen. Our unique TSA-based hydrogen purification process ensures consistent performance of the hydrogen purification plants, and offers economic advantages through increased hydrogen yield, reduced energy consumption, and improved space and cost efficiency.

Membrane-based Hydrogen Separation Technology

The membrane separation technology is a prevalent choice for extracting hydrogen from waste gases or other mixed gases. Central to this technology is a specialized polymer membrane, designed to filter the feed gas and separate hydrogen-rich permeates from other molecules. We have integrated a highly selective hydrogen-specific membrane with an average service life exceeding 10 years. Through meticulous adjustments to the membrane’s area and module configuration, our patented membrane separation technology enhances the purity and recovery rates of hydrogen, consistently achieving an 80-90% recovery rate for high-purity hydrogen.

CMM Concentration Technology for CNG and LNG Production

Our unique coal mine methane (CMM) concentration technology generates compressed natural gas (CNG) and liquefied natural gas (LNG) from sources like low-concentration coal mine gas, shale gas, and other methane-containing gas mixtures. As a pioneer in this domain, we introduced one of the first deoxygenation-specific sieve tailored to remove oxygen from low-concentration coal mine gas globally. Furthermore, we built one of the world’s first gas separation systems dedicated to converting coal bed methane into CNG. Our methane-specific and deoxygenation-specific sieves outperform conventional ones significantly in terms of adsorption capacity, and offer explosion suppression and protection. Leveraging the exceptional capabilities of our molecular sieves, our technology guarantees a safe and efficient methane production process, consistently meeting the stringent standards required for CNG and LNG.

CCS-EOR Technology for CO₂ Separation and Recycling

Our CCS-EOR technology is designed to separate and recycle carbon dioxide (CO₂) in crude oil recovery processes. We have developed CO₂-specific sieves characterized by their substantial CO₂ adsorption capacity and high CO₂/hydrocarbon separation efficiency. These proprietary sieves enable our technology to efficiently capture CO₂ from industrial source gases, achieving a purity level of ≥95 vol%. The compressed CO₂ is then injected into oil reservoirs as a displacement medium to enhance oil recovery, while the remaining purified gas is reintroduced into the natural gas grid. Compared to conventional adsorption or cryogenic approaches, our technology delivers a more cost-efficient and eco-friendly alternative for CO₂ separation and recycling.

Helium Purification and Recovery Technology

Our helium purification and recovery technology at ambient temperatures is tailored for use with helium-containing gas sources. This technology surpasses traditional cryogenic helium separation technologies in terms of its cost-effectiveness, streamlined and adaptable processing, and reduced energy consumption during operation. Our technology is also characterized by its secure and stable performance, achieving remarkable helium recovery rates of up to 99%.

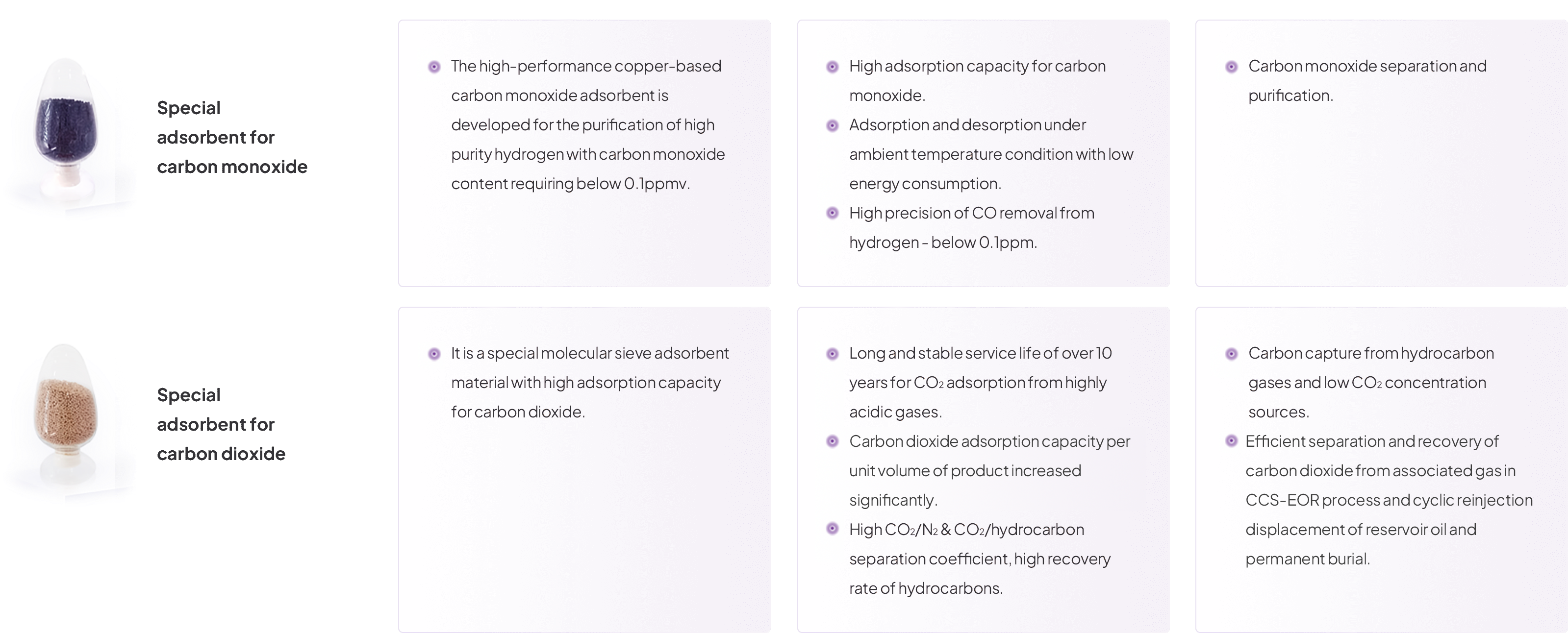

Molecular sieves play a vital role in gas separation and purification, largely determining the recovery rates, purity levels, and associated operational costs involved in gas production operations. Building on our decade-long technical research and field experience, our purification product portfolio includes 30 types of molecular sieves. Each of these sieves exhibits a strong affinity and selectivity for its targeted molecules.

The outstanding performance of our molecular sieves stems from our capability to fine tune the physical and chemical properties of absorbent materials. These alterations include modifications to molding, binder-free formula, pore distribution structure, surface polarity, and activation energy, all critical for the effective elimination of unwanted gases from feed gas streams.

For example, to address the challenges in hydrogen purification, we have utilized our unique formulation, structure design, and synthesis process to produce two specific molecular sieves for nitrogen (N₂), methane (CH₄), and carbon monoxide (CO) extraction. The conventional PSA process often encounters limitations due to lengthy adsorption-regeneration cycles, considerable adsorbent loadings, and significant equipment investments. Our innovations help accelerate the gas adsorption and desorption of molecular sieves and enhance their adsorption capacity, resulting in shortened cycles, improved production yield, and reduced energy consumption of the PSA process. Likewise, our proprietary technologies have yielded high-efficiency sieves that display potent and precise adsorption for CO and carbon dioxide (CO₂). These unique features of our proprietary molecular sieves contribute to an increased yield and reduced energy expenditures within our hydrogen and other gas production solutions.

On average, our proprietary molecular sieves deliver a significantly higher adsorbent capacity and separation coefficients than conventional adsorbents. Other features of our molecular sieves include rapid adsorption and desorption rates, superior precision in impurities’ removal, and long product lifespans. Under standard operating conditions, our PSA sieves can endure over ten years, while our TSA molecular sieves exhibit a lifespan of two to five years.

We offer customized solutions for the design, installation, and operation of efficient turnkey plants for the purification of hydrogen, and to a lesser extent, other gas products. Our extensive process engineering experiences enable us to provide comprehensive project management services, encompassing process design and optimization, procurement, installation, technology performance evaluation, technical support, equipment maintenance, and testing services during operation.

We specialize in delivering integrated, customized solutions that enable customers to produce hydrogen by purifying industrial waste gases – a process that is both economical and environmentally friendly. Typically, hydrogen-rich industrial waste gases, often generated from chemical and petrochemical manufacturing operations, account for approximately half of the country’s annual hydrogen production. These gases often contain a variety of impurities, such as sulfur, helium, oxygen, argon, N₂, CH₄, CO, CO₂, H₂O, and NH₃.

We tailor our hydrogen purification solutions after thoroughly analyzing the composition of feed gases and understanding our customers’ specific requirements. A typical hydrogen purification plant comprises multiple adsorption vessels to ensure a continuous supply of purified hydrogen, with each vessel filled with adsorbents that target and eliminate specific impurities. Building on our extensive project experiences, we optimize the selection, volume, and arrangement of various sieves to maximize purification efficiency. We also fine-tune crucial process parameters, such as pressure, temperature, cycle times, and the degree of control valve opening. These adjustments are tailored to best suit the intended application and the specific impurities in the feed gas.

It usually takes six to twelve months to complete a hydrogen purification plant in the design finalization stage. Once operational, a plant can function for approximately fifteen to twenty years, with a sieve replacement cycle of every two to three years. The resulting hydrogen product can reach a purity level of up to 99.999%. High-purity hydrogen has applications across diverse sectors, such as transportation, oil refining, semiconductor manufacturing, and chemical synthesis.

In addition to hydrogen purification from industrial by-products, we possess a range of other hydrogen production technologies, including natural gas conversion, coal gasification, methanol cracking, steam methane reforming (SMR), and ammonia decomposition. This comprehensive portfolio of technologies allows us to meet the varying hydrogen needs of customers in different scales. Beyond hydrogen, our separation and purification technologies can also produce an array of other high-purity gases, including CNG, LNG, helium, oxygen, N₂, CO, and CO₂.

Our expertise in providing integrated supply solution is exemplified by an excellent track record of over a decade, during which we have designed, installed, and operated over 170 hydrogen purification plants across China. As a testament to our strength in providing integrated supply solution, we hold a Grade GC(1) special equipment manufacturing license and qualifications for engineering project design, consultation, and construction in China. We manufacture and supply all the molecular sieves used in our hydrogen purification plants, while outsourcing the manufacturing of specialized control valves designed by us. Additionally, although we outsource the plant construction work to subcontractors, we maintain close oversight to ensure excellent quality.

Our comprehensive solutions offer flexibility to accommodate various feedstocks, catering to diverse gas purity requirements. Our extensive engineering and project experiences equip us to address complex challenges related to gas separation and purification, ensuring efficient and cost-effective implementation of turnkey plant. In particular, we specialize in creating customized plant designs that meet the unique specifications and requirements of our customers and achieve high levels of integration, automation, and modularity. Our solutions are recognized in the industry for their top-notch quality, high reliability, and highly effective purification processes.

Our client is a prominent chemical coal enterprise in Inner Mongolia, China. Its coal gasification process yields a significant amount of hydrogen-rich waste gases, typically carrying various impurities and contaminants. With the expansion of fuel cell vehicle usage in Inner Mongolia, there was an escalated demand for ultra-pure hydrogen to refuel these vehicles. The hydrogen gas produced by the client itself, however, fell short of the national purity levels required for fuel cell applications, necessitating enhanced hydrogen purification methodologies.